Using directional drilling & underground technology instead of ditching

Directional drilling & underground tech is a method of construction and installation of a new underground pipeline by putting the drill bit underground and using a large-capacity hydraulic jack to push the segments into the ground.

Using directional drilling & underground technology instead of ditching

Over the years, roads across the country have been continuously dug up and filled down to construct underground utility projects such as power lines, water, telecommunication cables ... Every rush hour, vehicles Traffic is very difficult, many places on the road surface are very dangerous for pedestrians. Facing the above situation, the state is planning to focus on the application of underground drilling technology in road digging, specifically using underground drilling technology with machines and robots.

Until now, we often use the method of ditching to construct and install utility underground works. However, the construction by the ditching method causes the road surface to be ripped up, the quality of the road surface is not guaranteed to seriously damage the road structure, resulting in the bearing strength. The road surface is greatly reduced, cannot be returned to the original state, causing subsidence. Some road digs have fixed barriers for a long time, causing traffic obstruction, causing huge social costs, which may be greater than the cost of construction. So why do we not apply horizontal directional drilling technology (HDD) to road drilling? Let Minh Phuong Investment Consulting & Construction Design Joint Stock Company help you solve this problem.

Directional drilling & underground tech

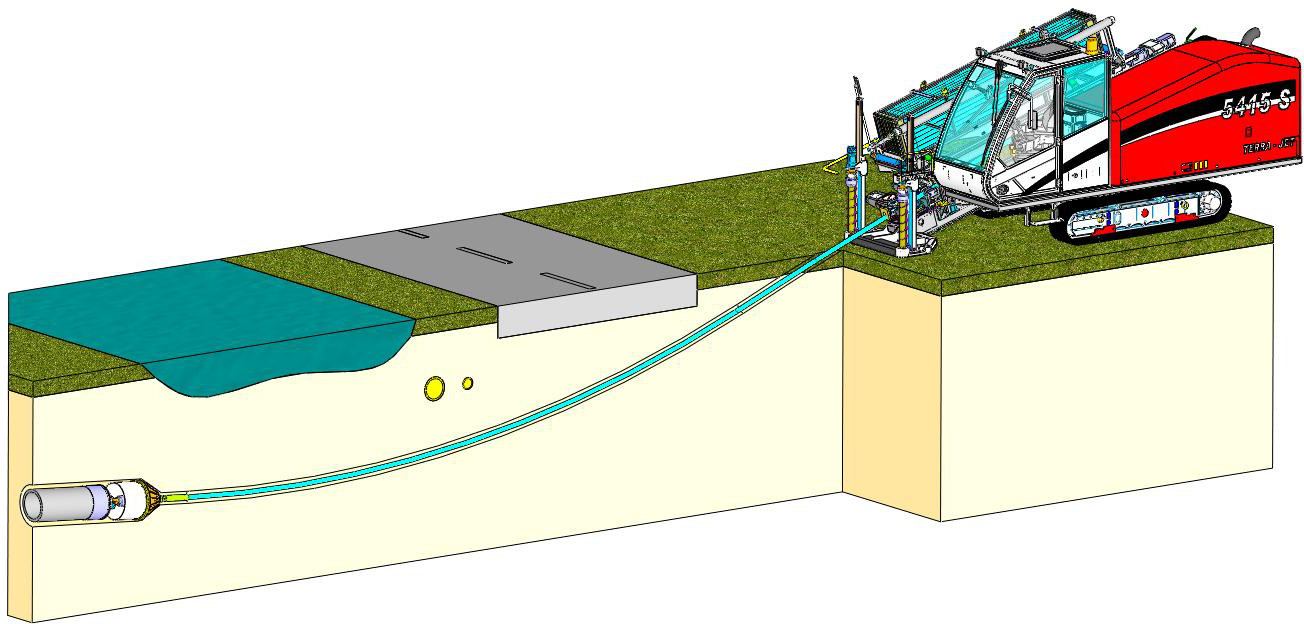

Directional drilling & underground tech is a method of construction and installation of a new underground pipeline by putting the drill bit underground and using a large-capacity hydraulic jack to push the segments into the ground. The drill bit can flexibly adjust, avoid existing underground works during construction; After completion, all data will be stored for future projects.

Not only that, the use of directional drilling & underground technology also has many advantages such as No need to dig a lot of soil causing dust, pollution, friendly protection of the environment, landscape and architecture, public structures. the process through which the pipe goes, reducing noise. Due to being buried deep in the ground, the work is safe, minimizing traffic jams and having little impact on people's lives. Because the machine operates on the crawler frame, it needs a small space to minimize the construction ground clearance for drilling and pull underground pipes, thereby saving construction time, construction costs as well as restoration and re-establishment. Low damaged works status. Especially, shortening construction time, reducing reconstruction costs thereby improving work efficiency. It can be said that the construction of underground drilling will overcome the above shortcomings of the trenching method.

Horizontal Directional Drilling technology (HDD)

Horizontal Directional Drilling (HDD) technology was born in the 60s in Los Angeles, derived from the idea of engineer Cherrington. HDD-oriented underground drilling technology is a method of construction and installation of new pipelines by controlled underground drilling, drilling direction, and can control the direction of the drill in the predetermined direction.

The horizontal directional drilling technology has many advantages such as high working efficiency, very economic efficiency, no influence on the surface, allowing control of the drilling direction and direction, thus having the most development advantage. compared to other grooved technologies.

The process of construction of underground drilling is simple and quick:

Consists of 02 phases

1. Update construction route information and route survey

2. Execution of pulling the HDD tube: includes 03 main steps

B1. Pilot bore: positioning the alignment by GPS

B2. Bore-back drilling and reaming.

B3. Pipeline installation.

Advantages:

+ Not digging roads, thus not affecting the road surface condition.

+ Do not cause traffic congestion when constructing in public places.

+ Do not affect the surrounding environment.

+ Convenience for the management, repair, and maintenance of equipment, pipes, and cables.

+ Fast and safe construction time

+ It is possible to construct through complex terrains such as highways, runways, railways, hills, riverbeds, canals ..., constructed at locations with limited premises.

+ Not having to relocate and handle intersection with other underground works.

+ The pipeline is installed correctly according to the design because the device can control the direction of the drill and the direction of the drill in the predetermined direction.

Application: HDD can be applied for different types of pipes:

+ Type of pipes: drainage, water supply, oil, gas, electric cables, telecommunication cables ...

+ Shape of tube: round.

+ Pipe materials: HDPE, PVC, steel, iron ...

In recent years, due to its outstanding advantages and large market potential, the HDD-oriented tube-pulling technology has been particularly interested in and widely used by countries.

In order to introduce and bring underground drilling technology to a wide application in Vietnam, Minh Phuong Corp is cooperating with many other underground drilling companies with the generation of underground drilling machines such as GS700-LS, Vermeer. units have a lot of experience and equipment in the field of construction works using directional drilling & underground technology HDD of New Zealand.

Currently, Minh Phuong Underground Drilling Company has brought the modern underground drilling equipment HDD to Vietnam. These underground drilling equipment are capable of constructing underground pipe installations up to 750 mm in diameter.

Specifications of the GS700-LS machine:

|

Model NO. |

GS700-LS |

Type |

Track |

|

Engine Power |

199kW |

Max Torque |

30000 N·m |

|

Max Mud Pump Flow |

600 L/min |

Trademark |

Goodeng |

|

Transport Package |

Nude Packing |

Specification |

9100*2280*2585 mm |

|

Origin |

China |

HS Code |

843041 |

|

Engine Power |

199 kW |

Max Torque |

30000 N·m |

|

Rig Weight |

15000 kg |

Dimension(L*W*H) |

9100*2280*2585 mm |

|

Max. Push & Pull Force |

700/1400 kN |

Max Rotation Speed |

125 r/min |

|

Max. Push & Pull Speed |

40 m/min |

Max Mud Pump Flow |

600 L/min |

|

Caterpillar Walking Speed |

3-5 km/h |

Max Mud Pump Rressure |

10 Mpa |

|

Enter Drill Angle |

12-22° |

Max Climbing Gradient |

18° |

|

Max Aperture Diameter |

Φ1500 mm(Soil Depended) |

Max Crossing Length |

900 m(Soil Depended) |

Along with the development and modernization of the city, the underground pipe network is becoming more and more complex, creating many challenges for the construction of underground drilling, requiring the application of high precision underground drilling technology. and short construction time such as directional drilling & underground technology HDD. In the near future, directional drilling & underground technology will be increasingly developed, the application scale will be expanded, and the underground drilling equipment is more modern to meet the rapid urbanization development.

Learn more Why choose Minh Phuong Corp?

CÔNG TY CP TƯ VẤN ĐẦU TƯ & THIẾT KẾ XÂY DỰNG MINH PHƯƠNG

Địa chỉ: Số 28B Mai Thị Lựu, Phường Đa Kao, Q.1, TPHCM

Hotline: 0903649782 - (028) 3514 6426

Email: nguyenthanhmp156@gmail.com

Xem thêm