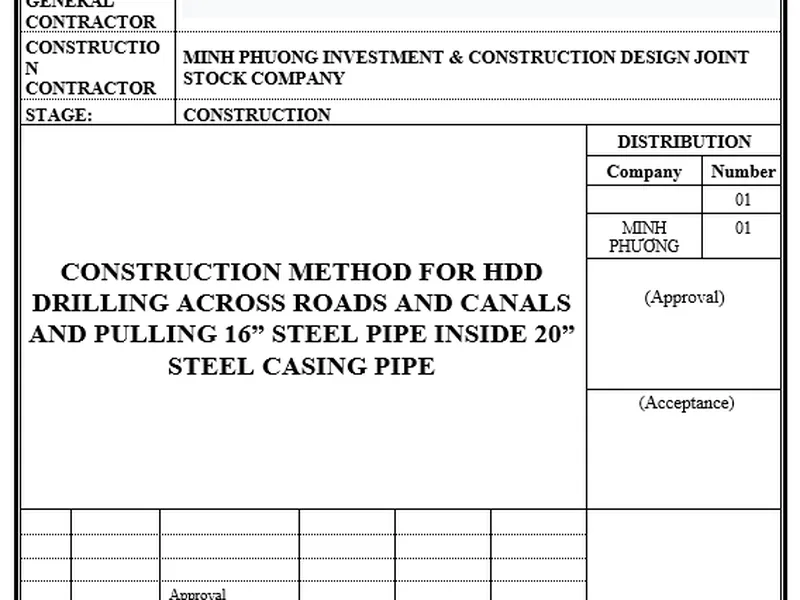

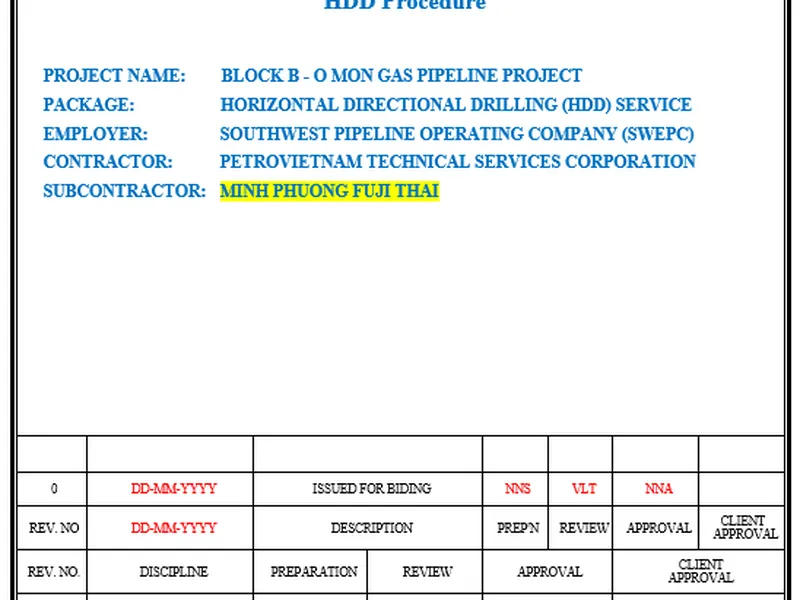

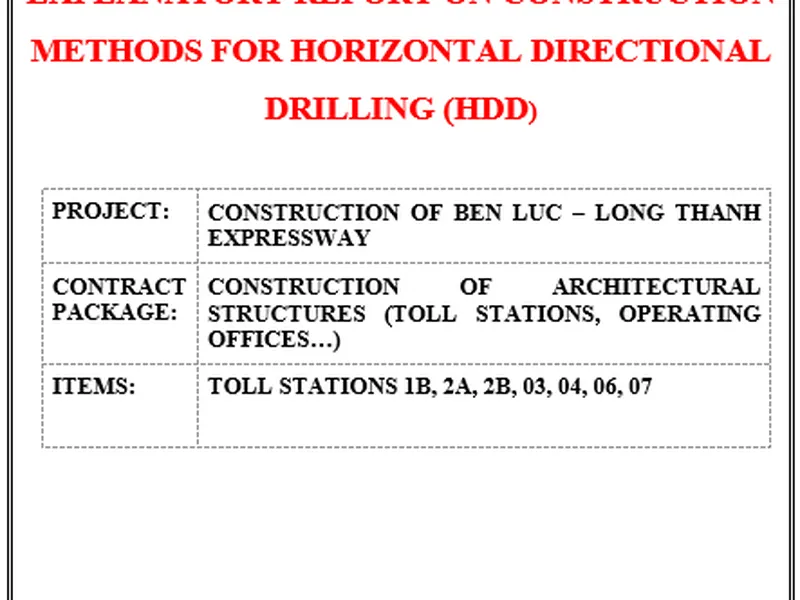

Drilling work to pull LNG pipes across the road for oil and gas companies in Ba Ria – Vung Tau

Here are a few pictures of the Drilling work to pull LNG pipes across the road for oil and gas companies in Ba Ria – Vung Tau:

The works of digging open roads to install underground works in Ho Chi Minh City mostly cause poor quality road surface after re-establishment. Many people ask why not apply underground pipe drilling technology instead of digging open roads?

According to the Inspector of the Department of Transport, recently renovated and upgraded the water supply pipeline on Trinh Van Can and Phan Van Trong streets (District 1). After construction, the contractor did not return the road surface to its original condition and convex surface. subsidence, subsidence.

Similarly, at the intersection of Nguyen Thi Minh Khai - Nguyen Thien Thuat (District 3), the plumbing repair unit also did not restore the road surface in its original state...

The people and the state both lose

Mr. Nguyen Van Dung, deputy director of the Urban Traffic Management Zone No. 1, said statistics show there are many mistakes in the excavation of the road surface. The contractor is slow to return the road surface and sidewalk; the dug hole is sinking, convex, water stagnant; materials and equipment are gathered on the sidewalks; construction over time...

Many construction contractors do not even restore the right quality pavement. Specifically, only rebuilding the road surface with a layer of medium-grained asphalt with a thickness of 12cm, not re-surfacing the road according to the regulations is two layers of asphalt (a layer of 7cm of medium-grained asphalt and a layer of 5cm of fine-grained asphalt). Or the underground drilling contractor re-establishes the sidewalk with bricks that do not guarantee the quality, so the bricks are peeling...

A traffic expert said that digging open roads makes the pavement structure not intact, so it quickly deteriorates. In fact, most of the open road excavation works have a width of 0.5 - 0.7m (belonging to projects to install power cables, telecommunication cables, etc.), and open road excavations have a width of 1 - 2,5m (belonging to the project of installing water supply pipes and drains) all affect people's lives.

In which, the road surface excavation work with a width of 2 - 2.5m had to build a "blockhouse" and the construction lasted for several months, making it difficult for people to travel and inconvenience in trading.

Mr. Nguyen Tat Han, the deputy chief inspector of the Department of Transport, said that the digging of open roads caused damage to the State as well. "Open road excavation works with narrow excavation lanes lack compaction construction equipment, equipment that does not guarantee the compaction of the roadbed, causing the road surface to sink" - Mr. Han said.

It is expected that in 2021, the focus will be on switching to underground jacking technology

Mr. Nguyen Tat Han said that the number of private cars is increasing rapidly, causing the traffic density on the road to be crowded, so the digging of open roads leads to increasing traffic jams. Therefore, the solution of underground jacking instead of open excavation should be quickly applied.

Similarly, Mr. Nguyen Van Dung believes that underground drilling will overcome the shortcomings of open-road excavation.

According to Mr. Dung, in the past time, several projects have used underground jacking drilling technology or oriented drilling to install underground works such as environmental sanitation projects, sewer installation projects across National Highway 1 and above. Some roads are forbidden to dig. Therefore, the management units need to research and apply this new technology instead of digging open roads.

Mr. Vo Khanh Hung, deputy director of the Department of Transport, said that the application of underground drilling technology in underground works will limit the impact on people, ensure environmental sanitation, and speed up the construction progress. compared to open road excavation.

According to Mr. Hung, to apply this new technology, the department will request the Institute of Economics to calculate and give an estimate of the unit price for investors to put in the project. Besides, the Department of Transport will discuss with the units of electricity, water supply, drainage... to calculate the application of this new technology for construction on suitable roads so as not to affect underground works. very complex was installed decades ago.

According to Mr. Hung, the Department of Transport is expected 2021 to apply underground jacking technology to construct and install underground works throughout the city.

Drilling and pulling underground pipes for fast construction

According to Mr. Vo Khanh Hung, in Ho Chi Minh City, Minh Phuong Construction Design and Investment Consulting Joint Stock Company, abbreviated as Minh Phuong Corp, applies underground pipe drilling in the construction of transportation infrastructure projects. pine. Ho Chi Minh City encourages more contractors to build with this new technology to create competition.

Recently, Minh Phuong Corp has carried out a project to drill a 500m underground pipe across Mai Chi Tho Boulevard (District 2) in 35 days, while it takes up to 70 days to dig an open road.

At the same time, the unit implemented a project of installing traffic surveillance cameras on National Highway 1 (from An Suong to An Lac roundabout) 14km long by underground jacking technology with a time of 56 days, while digging the open road. it takes 1 year.

Currently, Minh Phuong company is in the process of implementing the project of drilling to pull LNG pipes through road 965 for oil and gas companies in Ba Ria - Vung Tau. Here are a few pictures of the Drilling work to pull LNG pipes across the road for oil and gas companies in Ba Ria – Vung Tau:

Cross-road drilling hole at the drilling project to pull LNG pipe across road 965 for oil and gas company in Ba Ria - Vung Tau.

Underground pipes are pulled across the road

Drilling to pull the LNG pipe across the road was successful

Lean more Drilling project across the D56mm iron pipe traction line in Phu My Industrial Park

CÔNG TY CP TƯ VẤN ĐẦU TƯ & THIẾT KẾ XÂY DỰNG MINH PHƯƠNG

Địa chỉ: Số 28B Mai Thị Lựu, Phường Đa Kao, Q.1, TPHCM

Hotline: 0903649782 - (028) 3514 6426

Email: nguyenthanhmp156@gmail.com

Xem thêm