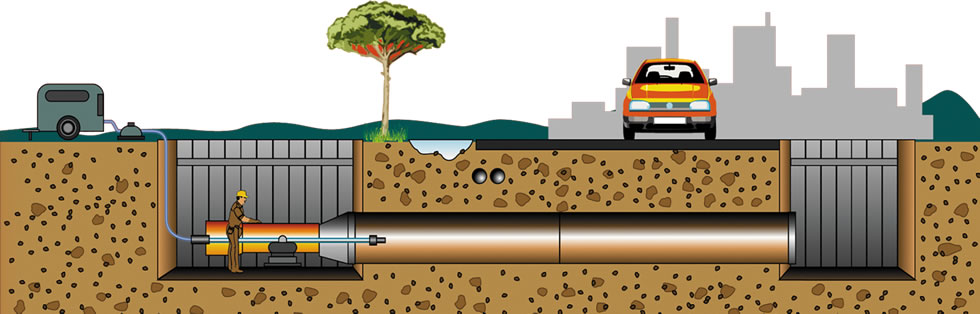

Pipe jacking auger method

Pipe Jacking auger method is a technology for installing pipes in the ground, hydraulic jacking equipment is used to excite pipe joints in series synchronously according to the construction speed of the drill head from one jack to another, receiving well to create a long and smooth pipe.

Pipe Jacking auger method is a technology for installing pipes in the ground, hydraulic jacking equipment is used to excite pipe joints in series synchronously according to the construction speed of the drill head from one jack to another, receiving well to create a long and smooth pipe. This Pipe Jacking technology is applied in the construction of water supply and drainage systems, electricity, telecommunications, ... works that cross the road with high traffic density, it is impossible to construct open excavation from the top down because there are many underground utilities, river crossings, railways or in cases where pipes must be installed in deep locations.

Pipe Jacking technology first appeared in 1910 in the United States, by 1960 the basic principle of this technology was elaborated in detail by the American underground pipe jacking association. Since the 1970s, Pipe Jacking technology has been applied and developed in Japan. By the 1980s, Pipe Jacking technology was applied and developed in Europe. In Vietnam, Pipe Jacking technology has been successfully applied since 2008 at the HCMC water environment improvement project. Ho Chi Minh phase 1.

Advantages and scope of application of Pipe jacking technology:

Can be applied to different depths. Economic depth to apply the underground pipe jacking method when the buried depth is ≥ 6m.

Less impact on the ground and other structures above, low risk of subsidence.

Minimizing the amount of excavation and reclamation work.

Less impact on the environment and people around the construction area compared to the traditional open excavation method.

Pipe jacking drills are used for the construction of water supply and drainage systems, gas and oil pipeline systems, electrical and telecommunications cables.

Can be used to pass through roads, railways, canals, rivers, buildings, etc., in pipeline construction projects.

Another special application is a pedestrian tunnel, a connection between two tunnels.

Construction process

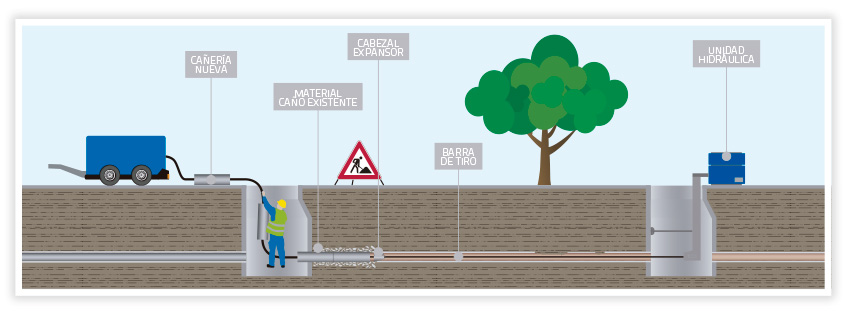

The construction process of underground pipe jacking drilling consists of 5 basic steps:

Step 1: Build jacking holes, receive pits, and reinforce the ground

Step 2: Install construction equipment line

Step 3: Open the tunnel door and drill the first culvert

Step 4: Construction of the next pipes until the receiving pit

Step 5: Complete the pipeline and clean the ground

Typical projects

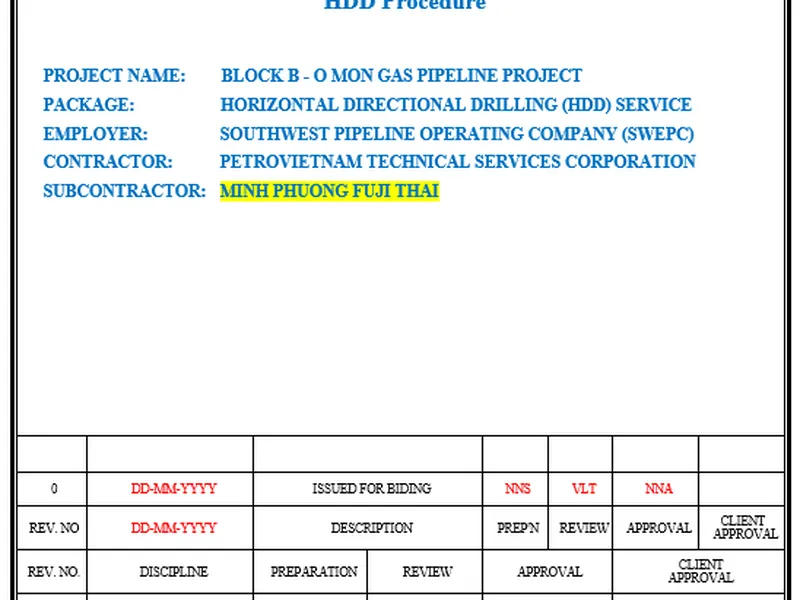

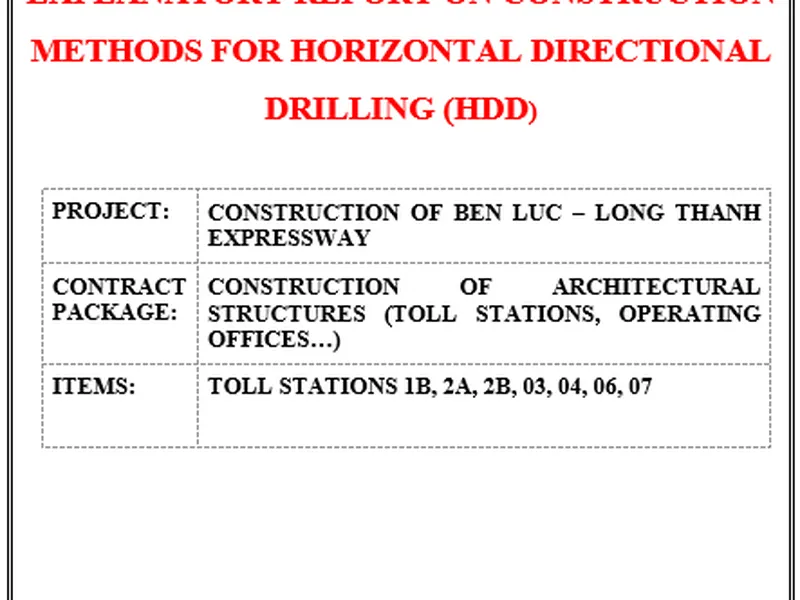

Project: Cai Mep-Phu My pipeline and Phu My gas distribution station (Phase I)

Category: Underground drilling and pipe drawing

Location: Cai Mep Industrial Park, Phu My Industrial Park, Phu My Town, Ba Ria - Vung Tau Province

Cai Mep-Phu My pipeline and Phu My gas distribution station (Phase I)

Underground drilling and pipe drawing

Illustrated construction sequence:

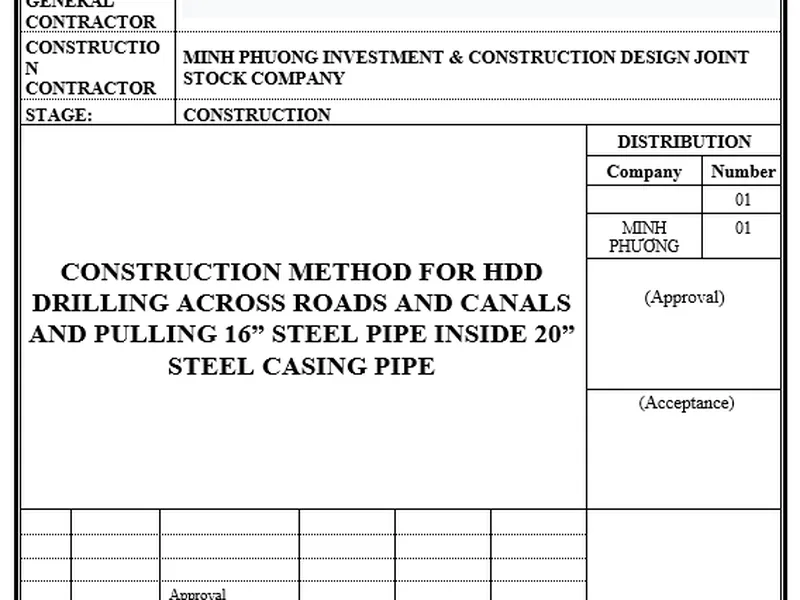

CÔNG TY CP TƯ VẤN ĐẦU TƯ & THIẾT KẾ XÂY DỰNG MINH PHƯƠNG

Địa chỉ: Số 28B Mai Thị Lựu, Phường Đa Kao, Q.1, TPHCM

Hotline: 0903649782 - (028) 3514 6426

Email: nguyenthanhmp156@gmail.com

Xem thêm