Pipe jacking vs directional drilling

The pipe jacking auger method is a technique for installing underground pipes. pipe jacking construction method is used to push the special tubing into the ground with the front-mounted machine head.

Pipe jacking vs directional drilling

Pipe jacking auger method

The pipe jacking auger method is a technique for installing underground pipes. pipe jacking construction method is used to push the special tubing into the ground with the front-mounted machine head. There is no technical limitation concerning the length of each trigger line, however technical practical problems and economics may impose some limitations. The trigger line can be straight or curved with one or more different curvature radii.

The pipe jacking auger method can support soil and reduce soil movement.

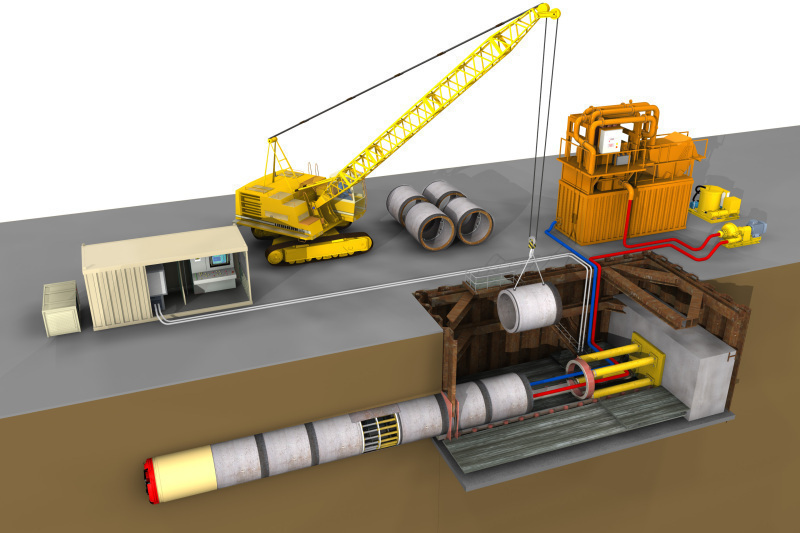

Pipe jacking process

The pipe jacking process of the pipe jacking auger method is implemented through the following steps:

1. Surveying the conditions and conditions of the ground before construction and measuring and determining the construction site.

2. Construction of jack and receiving wells.

In Vietnam, jack wells and wells for construction of drainage systems can be constructed in 2 types:

- Caisson

- Close to Larsen

Wells and wells received design calculations based on the available geological survey results.

3. Precisely position the soft eye position at the jack well outlet and inlet well.

Soft eye positioning is based on the design elevation of the bottom of the drain.

4. Transport the pipe jacking equipment and jacks to the site.

Jacking culverts have a different structure from open excavated construction culverts to be suitable for pipe jacking. There are 3 types of jacks:

- Standard pipe: This culvert has a normal structure, only a look at the hook to lower the sewer to the jacking position.

- Bentonite pipe sewer (Grouting pipe): This sewer has the same structure as a normal sewer but has 3 additional holes arranged 120o apart according to the circumference of the sewer to serve the pumping of Bentonite mortar for lubrication around the sewer wall.

- Intermediate pipe: This is a pair of sewers including a Male pipe and a Female pipe. Intermediate jacks are arranged between these two sluices. After the whole jacking of the entire sewer line is completed, the intermediate jack is dismantled and pushed snugly together.

5. Installation of ground support equipment for jacking work: Crane trucks, mud settling tanks, mud suction trucks, generators, Bentonite pumping stations.

The bentonite pumping station has the purpose of pumping Bentonite mortar to the outside around the pipe body to reduce the friction force between the soil and the pipe wall.

6. Installation of supporting equipment in wells serving pipe jacking work: mud pump system, ventilation system, control system, hydraulic system, electrical system, bentonite pump system, conduction system direction by laser, water-blocking gaskets, jet wall.

7. Install the main jacking system and connect with the supporting devices: Hydraulic jack, push jack ring: contact ring between the drain and main jack, drill head, intermediate jack (if any)

8. Operate the jacking system to put the drill head into the ground to start the pipe jacking work. Install successive culverts behind the drill head and intermediate jacking stations (if necessary) until the drain and the drill head enter the receiving well.

In the pipe jacking process, it is necessary to monitor the main trigger force. If the main jacking force is too great to break the drain, then it is necessary to install intermediate jacking stations to reduce the main jack force.

Locations of intermediate trigger stations are determined based on calculations.

9. At the location of the receiving well, install the receiving jack and jack-head receiving frame.

10. Transport the drill head and the supporting equipment in the tunnel out of the receiving well. Clean the construction site according to regulations.

Application of pipe jacking auger method:

Main applications of jacking drill include construction of new drainage systems, replacement of sewers, main water pipes, gas, oil, electrical cable installation, telecommunication cables.

Special applications include the installation of rectangular or circular tunnels used as pedestrian tunnels, underground passages.

Can be used to overcome obstacles such as highways, railways, canals, barrier buildings, and airports in pipe installation projects.

Advantages:

a. Technically:

Can be applied at different depths. Usually, the economic depth to apply the pipe jacking method is when the pipe buried depth is ≥ 6m. At lower depths, the pipe jacking method is considered concerning many other factors such as finance, environment, ...

Prevent the penetration of groundwater with watertight gaskets.

Low risk of subsidence.

Minimal disturbance on the ground.

Minimize the volume of earthwork, reconstruction work.

Little effect on other technical infrastructure works.

b. In terms of the environment:

The environmental advantage is due to the application of pipe jacking when compared to the traditional open excavation method. Normally, with the no-digging method, the volume of materials "coming" and "going" will be reduced along with the reduction of soil filling and reclamation work.

Table comparing the environmental aspects of the two construction methods of installing open culverts and pipe jacks.

In many cases, the use of pipe jacking techniques instead of open excavation will bring a positive impact on the safety at the workplace, on the lives of people around the construction site, on the local environment.

Learn more Drill across and drill through road, Natural gas line installation

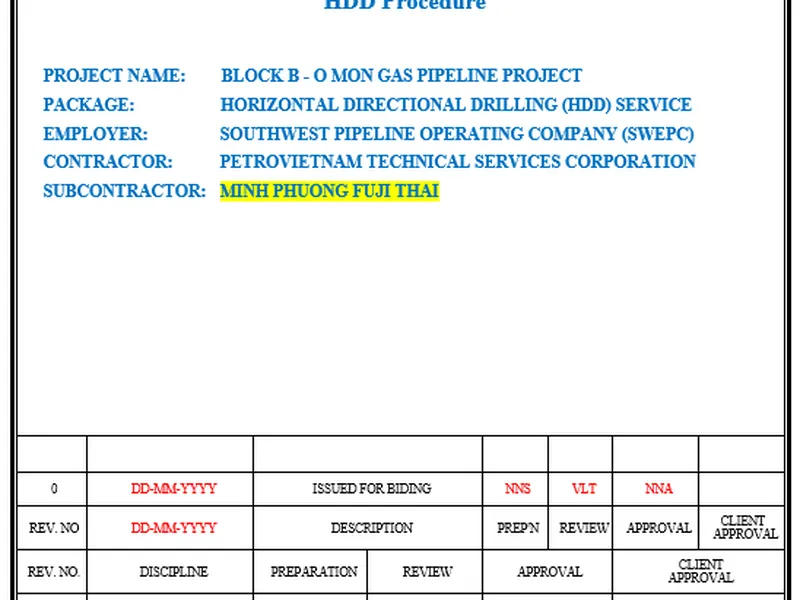

CÔNG TY CP TƯ VẤN ĐẦU TƯ & THIẾT KẾ XÂY DỰNG MINH PHƯƠNG

Địa chỉ: Số 28B Mai Thị Lựu, Phường Đa Kao, Q.1, TPHCM

Hotline: 0903649782 - (028) 3514 6426

Email: nguyenthanhmp156@gmail.com

Xem thêm