UNDERGROUND CABLE INSTALLATION METHODS

Underground cable installation equipment will carry tons of cables and at a slow speed, the vessel will slowly spread the cable to the seafloor according to detailed instructions of the network provider.

UNDERGROUND CABLE INSTALLATION METHODS

Do you know, the Internet you are using is provided from the sea cables running across the ocean and to get those network connections, human and energy are wasted a lot.

Underground cable installation equipment

Install submarine cables on the seabed by ships specially designed for this job. Underground cable installation equipment will carry tons of cables and at a slow speed, the vessel will slowly spread the cable to the seafloor according to detailed instructions of the network provider.

How to install underground cable

Typically, a dedicated ship will carry about 2,000 kilometers of cable.

Depending on the ship's equipment, type of vessel, weather conditions at sea, and topography of the seabed, a single vessel can spread 100 to 150 kilometers of cable per day. Newer, more modern ships can cover more than 200 kilometers of cable.

The cables themselves are also designed to withstand the extreme conditions of the seabed as well as extreme water pressures. However, the cable line can still be broken for many reasons, from natural factors to human factors.

CT scan of fiber optic cable.

1. Polyethylene layer - a waterproof, non-conductive plastic that is a very good barrier to water and air.

2. The insulation tape is made from Polyester.

3. The steel ropes are bundled into a resistant layer.

4. The aluminum layer prevents water.

5. Polycarbonate.

6. Aluminum/copper pipes.

7. Wax is made from petroleum (very common, eg Vaseline contains 100% of this wax).

8. Fiber optic cable.

These fiber optic cables carry optical signals that are transmitted by wavelength-based optical multiplexing, with transmission rates of up to terabytes per second. Besides, cable manufacturers use optical repeaters to increase the strength of the waves when traveling long distances. The entire cabling system is powered by electricity running in copper pipes in the cable.

The lifespan of the above underground cables is about 10 years, the cost of production and installation depends on the length of the cable line. Underground cable installation methods? On average, a project to install a submarine cable across the river or the sea can be worth about $ 100 million to $ 500 million.

We also do not use satellite networks to replace undersea cables because the cost of terabytes of data per line will cost no less than a billion dollars.

The thickness of the cable depends on where it will be installed. Thin cables are used for shallower seas and obviously, an underground cable laying diagram of more than 600 meters thick cable will be used. Such cables can withstand 840 kg / cm2 up to 1500 kg / cm2. As you know, the pressure on the seabed is so great, the optical fiber must be able to last for a long time.

Underground cable installation jobs

The laying process will start from the station located on the shore, the cable end will be extended from the station to the ship located offshore. After the cable from the shore is connected to the end of the cable on the ship, the train will begin a continuous spreading process until it reaches the next station on the other side.

The spreading of the cable is also often kept secret, underground cable installation companies will try to keep it as private as possible. Only a handful of units are known to have the cable line installed, that is the municipal government where the cables are installed, the port operators, or the shipping companies that routinely pass through the area. They did this to avoid the curious residents around them coming back to watch it or worse, cutting off the cable and selling it.

Underground cable installation companies

The undersea cable market is dominated by European companies, and Japan is the second-largest country in this market. In general, when compared to other countries, Vietnam is a small country in this industry.

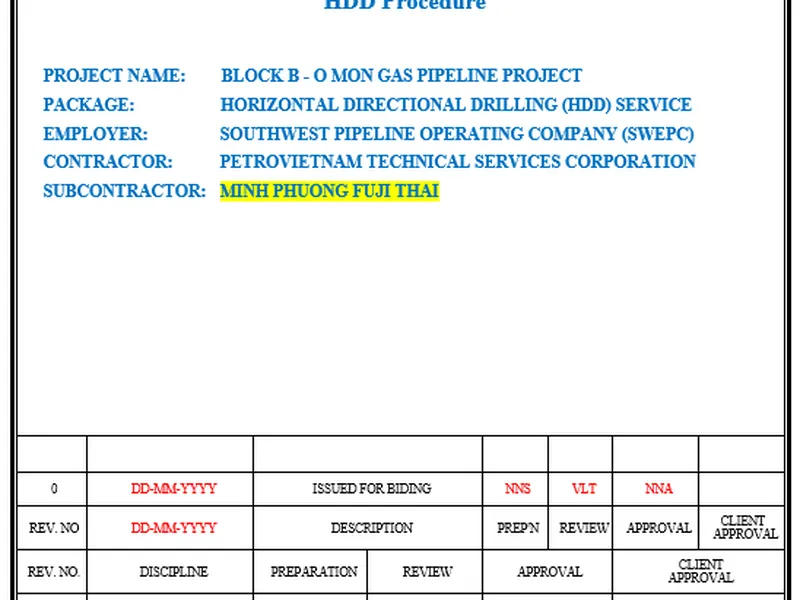

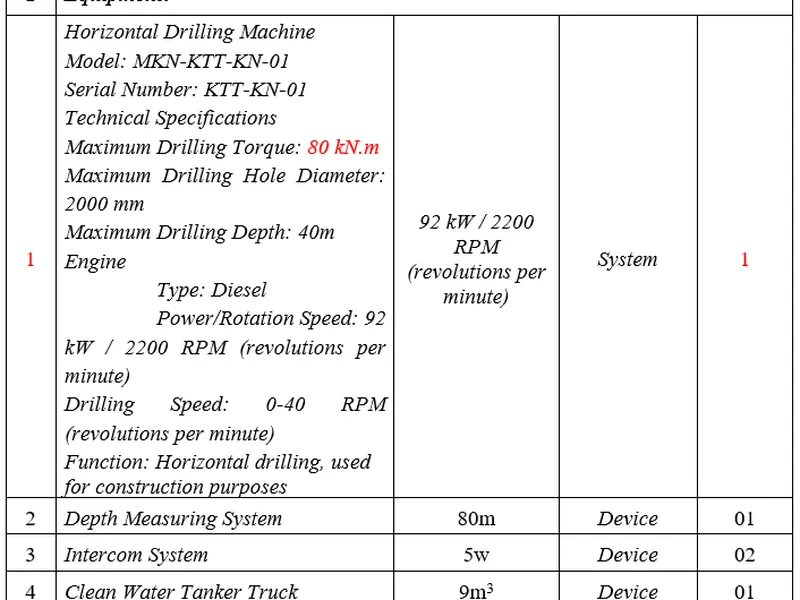

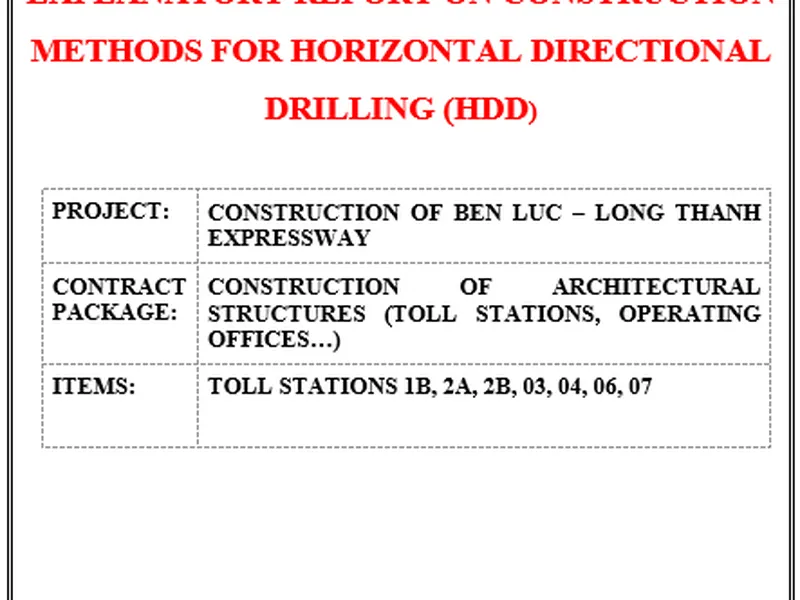

To help customers have more choices in the underground installation of pipes, as well as to install underground optical cables across roads and rivers; Minh Phuong Corp company has deployed to provide more services "Drilling across the road, across the river pulling underground cables". This is a traditional underground drilling method that is often applied for underground installation of short-distance pipes and narrow equipment space that "Robot Drilling" cannot meet.

Minh Phuong Corp's underground cable installation machine system is operated based on the operation process of the Robot drilling machine. This is the difference that Minh Phuong Corp wants to bring to customers: "Drilling robot, horizontal drilling price"

Based on the experience gained from the robot drilling technology, "Drilling across the road, across the river" of Minh Phuong Corp will basically meet the complex geology such as sand, small rocks, mud ... commonly encountered in the underground drilling construction process. We always want to bring to customers the service with the following criteria: "Safety, Quality, and Progress".

Learn more Using directional drilling & underground technology instead of ditching

CÔNG TY CP TƯ VẤN ĐẦU TƯ & THIẾT KẾ XÂY DỰNG MINH PHƯƠNG

Địa chỉ: Số 28B Mai Thị Lựu, Phường Đa Kao, Q.1, TPHCM

Hotline: 0903649782 - (028) 3514 6426

Email: nguyenthanhmp156@gmail.com

Xem thêm