Underground drilling technology is most used today

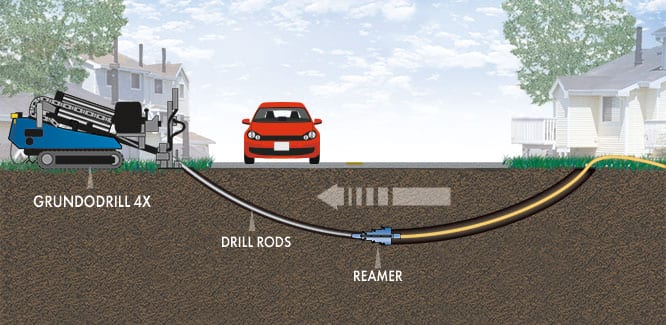

Directional drilling & underground tech is a method of construction and installation of a new underground pipeline by putting the drill bit underground and using a large-capacity hydraulic jack to push the segments into the ground.

Underground drilling technology is most used today

Horizontal drilling is commonly used in bridges, roads, ... popular in many urban areas, densely populated areas. As a result, it helps to save costs and construction manpower.

The technique of drilling with direction across the road is commonly used in today's projects. This use of underground drilling gives many advantages to the entire project instead of backlog such as grooved structures. So how is horizontal drilling done? Let's find out right below.

Prepare before performing underground drilling

Before drilling, the construction party needs to identify the following issues:

- Drilling direction

- Obstacles

- Underground path

Horizontal drilling way

After the above problems have been identified, the executor conducts directional drilling on the braking or crossroads, which is usually a cross-section option. By using drilling technology you will create an obstacle avoidance tunnel and make connections. Of course, the drill line does not have to be straight.

When applying this underground drilling technology, the units often prioritize the use of compact underground and surface exploration drilling equipment, horizontal drilling under the highway, crossing rivers, or over residential areas. Under the connecting drill tunnel is a horizontal drill line that is carried out just below the surface.

In general, horizontal drilling is often applied by construction units in today's underground works. , This underground drilling technique brings many benefits to the population as well as the whole city such as reducing traffic congestion, avoiding breaking old infrastructure connections, not drilling open, causing loss of area,...

Horizontal drilling technology is also known as underground drilling with guide Robot makes drilling easier, deeper, and faster. Let's learn about this technology in the following article!

Nowadays, in addition to vertical drilling from top to bottom, with terrain requiring horizontal drilling, horizontal drilling technology has been successfully created. The technology is also known as underground horizontal drilling HDD.

What is horizontal drilling technology?

Horizontal drilling technology is understood to be an underground drilling method with controlled drilling. In this technology, the direction of the drill bit will be controlled according to the predetermined drilling direction.

The purpose of horizontal drilling is to pass pipes across the road for the underground stages of electricity or water supply and drainage. The process of using this technology should ensure that no traffic affects the traffic.

Essential equipment for the horizontal drilling technology by Guide Robot

To conduct drilling using this technology, the following equipment is required:

The drilling rod is a specialized rod, hollow inside to transfer the drilling solution to the tip of the drill and has high elasticity.

Guide drill: must be a drill fitted with a radio device, with high strength and rigidity.

A radio detector is an automatic radio device capable of automatically detecting and displaying the drilling position and direction so that the operator can control and control the drilling direction more easily.

To conduct underground drilling, the following 25-piece oblique drill kit will be an effective "assistant" for you. Find out more details about this kit in the following article!

A multi-purpose, dedicated bevel drill kit is required to perform bevel drilling. Therefore, the following article will introduce you to a 25 part bevel drill kit manufactured in ABS plastic with alloy bevel holes. Let's find out the information related to this product right away!

Specifications of the product

Product size: 160mm x 90mm x 70mm.

Quantity: 01.

Bore size diameter: includes 4 types of diameters 6, 8, 10, and 12mm.

Two beveled holes with a diameter of 9.5mm.

Drill skewers at an angle of 10 degrees.

The holes are made of alloy, ensuring high drilling precision.

Introduction to the 25-piece bevel drill kit

The product is manufactured from ABS plastic with high hardness, solid but not brittle. Therefore, this device is able to withstand impact, the toughness changes small when in a low-temperature environment. As a result, users will have complete peace of mind about the durability and reliability of this oblique drill kit.

For carpenters, especially in the production of wooden furniture, precision is required. So this 25 part bevel drilling kit with the combination of straight and bevel drilling and a variety of drilling diameters will be the smart choice of consumers.

Above is all the information about the batter drill kit consisting of 25 parts. Currently, the product is available on the market, so you can find and buy the kit very easily.

Ground penetrating radar (GPR)

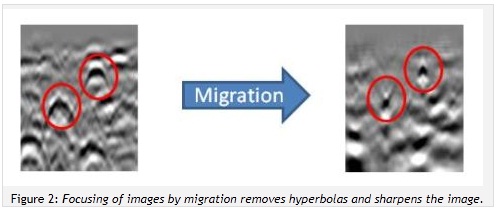

Georadar technology, also known as Ground Penetrating Radar (GPR) is a phrase applied in infinite technology, in the 1-1000 MHz range, to study the structure and properties of matter. below ground (possibly man-made). In the past, trans-ground radar was mainly used for structural mapping in soil, recently it is used to check geological structures that do not require digging.

In recent years, cross-ground radar surveys have been carried out in many countries around the world. Since 1988, there has been an International Conference on GPR every two years. The scientific reports together with the results of the application of the radar method have greatly increased in both quantity and quality. This proves that this new method, along with its modern equipment, has been confirmed by scientists in the field of Geophysics for their indispensable role in the research and development of technical geophysics and geography. Environmental Physics.

Processing GPR data using filtering algorithms, which filter the noise caused objectively and objectively. The radar section is a general picture reflecting the detailed geological structure of the investigation area, GPR equipment has been used in geotechnical and environmental survey research for basic investigation and exploration. Geological…. detail:

- Surveying the foundation works to build roads, bridges, airports, ports, etc...

- Detecting foreign objects, geological structure boundary, hidden location related to landslide

- Surveying underground water, assessing pollution, and determining water layers

- To explore and search for minerals, the depths of bedrock and ore seams in the mines

- Application in archeology

- Identify types of underground pipes, underground cables, foreign objects in the landfill that have been buried before.

- Locate gaps and defects in coal dams, dike bodies

Above is basic information about horizontal drilling technology as well as how to perform directional drilling techniques. Hope this article has brought you useful information related to this new construction technology.

Learrn more Using directional drilling & underground technology instead of ditching

CÔNG TY CP TƯ VẤN ĐẦU TƯ & THIẾT KẾ XÂY DỰNG MINH PHƯƠNG

Địa chỉ: Số 28B Mai Thị Lựu, Phường Đa Kao, Q.1, TPHCM

Hotline: 0903649782 - (028) 3514 6426

Email: nguyenthanhmp156@gmail.com

Xem thêm